Trump’s 50% Steel Tariffs: Supply Chain Disruption Explained

Trump’s 50% Steel Tariffs: Industry Pushback and Supply Chain Disruption…

Trump’s 50% Steel Tariffs: Industry Pushback and Supply Chain Disruption…

Businesses approaches to supply chain management were drastically altered by…

A quick summary and overview Cross-docking transforms traditional logistics by…

Handling Hazards: How WHMIS-Compliant Logistics Protect Your Homecare Brand A…

Cross-docking transforms traditional logistics by eliminating unnecessary storage and handling steps. Instead of warehousing products for extended periods, items move directly from inbound to outbound vehicles with minimal dwell time. This streamlined approach reduces costs, accelerates delivery times, and enhances supply chain efficiency. For Canadian businesses facing logistics challenges, cross-docking offers a strategic solution that improves inventory management, supports just-in-time distribution, and promotes sustainability. MacMillan Supply Chain Group provides comprehensive cross-docking services that help companies optimize their logistics operations while meeting customer demands for faster, more reliable deliveries.

In today’s fast-paced business environment, efficiency isn’t just a goal—it’s a necessity. Cross-docking represents a revolutionary approach to logistics that’s changing how products move through supply chains across Canada and North America. But what exactly is it? Cross-docking is a logistics practice where products from incoming shipments are unloaded, sorted, and directly loaded onto outbound transportation with minimal or no storage time in between.

Think of it as a well-choreographed dance: goods arrive at a distribution facility, move across the “dock” (hence the name), and depart to their next destination—all within hours, not days or weeks. This process eliminates traditional warehousing steps, reducing handling costs and accelerating delivery times. For businesses in Toronto, Calgary, Vancouver, or those managing cross-border shipping between Canada and the US, cross-docking offers a competitive edge in today’s speed-focused marketplace.

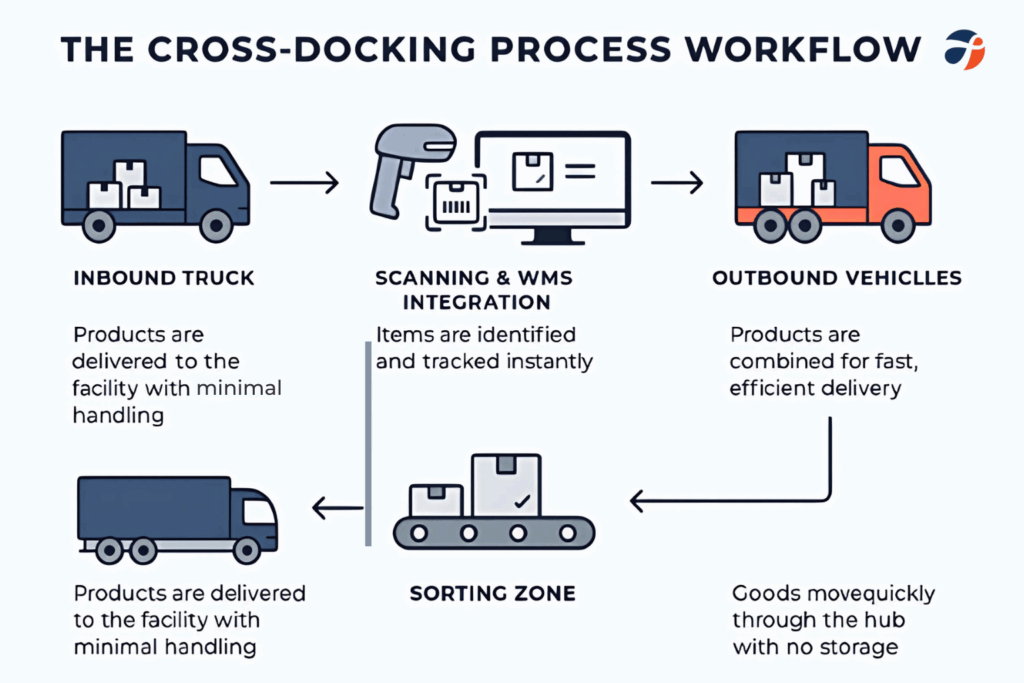

Cross-docking transforms logistics operations through a simple yet powerful concept: keep products moving. Unlike traditional warehousing where items might sit in storage for weeks, cross-docking facilities function as transfer points where goods typically remain for less than 24 hours.

The process begins when inbound trucks arrive at designated doors of a cross-docking terminal. Workers quickly unload these shipments and sort them according to their outbound destinations. Some facilities use sophisticated conveyor systems that automatically scan and route items to the appropriate loading areas. Others rely on manual sorting with clear floor markings and staging areas. Either way, the goal remains the same—minimize handling and maximize flow.

For this system to work effectively, timing is everything. Inbound and outbound schedules must be carefully synchronized. This is where warehouse management systems become essential, providing real-time visibility and coordination. These systems track every item from arrival to departure, ensuring nothing gets lost in the shuffle.

Canadian distribution centers often adapt cross-docking to address unique regional challenges. For example, Toronto logistics solutions might emphasize cross-border capabilities, while Calgary cross-docking operations might focus on connecting western Canadian markets efficiently. The beauty of cross-docking lies in its flexibility—it can be customized to meet specific business needs while maintaining core efficiency principles.

Why are more Canadian businesses embracing cross-docking? The advantages extend far beyond simple cost savings. First and foremost, cross-docking dramatically reduces inventory holding costs. When products don’t sit in warehouses, you avoid expenses related to storage space, insurance, and inventory management. For businesses in expensive urban markets like Toronto or Vancouver, this space saving translates to significant financial benefits.

Transportation efficiency represents another major advantage. Through freight consolidation services, cross-docking allows multiple smaller shipments to be combined into fuller truckloads. This consolidation reduces the total number of trips required, cutting fuel consumption and transportation costs by 25-30% in many cases. For companies managing cross-border shipping between Canada and the US, these savings can be substantial.

Speed to market gives cross-docking users a competitive edge. In retail and e-commerce fulfillment, reducing delivery times by even a day can significantly improve customer satisfaction. Cross-docking supports just-in-time distribution models, allowing businesses to respond quickly to market demands without maintaining excessive inventory.

Product quality benefits too, especially for time-sensitive goods. Fresh food, pharmaceuticals, and seasonal items spend less time in transit, reducing the risk of damage or obsolescence. This is particularly important in Canada’s varied climate zones, where temperature control during shipping presents ongoing challenges.

Finally, cross-docking supports supply chain optimization by increasing visibility and control. With products spending minimal time in the system, managers can track inventory more accurately and respond faster to changing conditions.

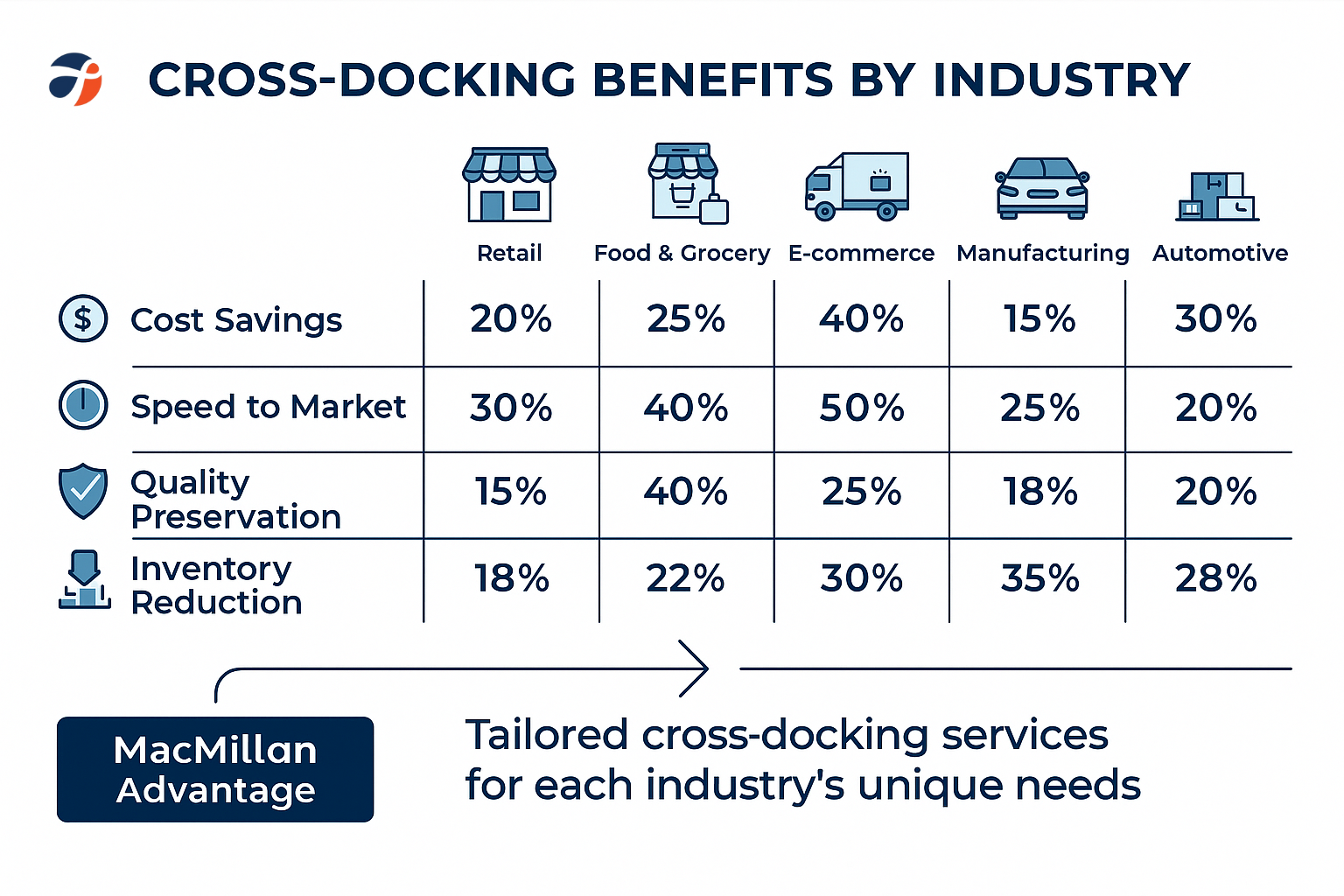

While cross-docking offers advantages for many businesses, certain industries see particularly impressive results. Retail stands at the forefront, with major chains using cross-docking to replenish stores quickly and efficiently. Rather than sending individual shipments from multiple suppliers to each store, retailers consolidate these deliveries at cross-docking facilities. This approach has helped Canadian retail chains reduce inventory costs by up to 15% while improving on-shelf availability.

The food and grocery sector benefits enormously from cross-docking’s speed. Fresh produce, dairy, and frozen goods require rapid handling to maintain quality and shelf life. Cross-docking facilities equipped with temperature-controlled zones ensure these products move quickly from producers to grocery shelves. Montreal warehouse operations specializing in food distribution often use cross-docking to serve Quebec and eastern Canadian markets efficiently.

E-commerce fulfillment in Canada has embraced cross-docking to meet rising consumer expectations for fast delivery. Online retailers use these facilities to sort incoming inventory directly into outbound customer orders, dramatically reducing processing time. This approach supports same-day or next-day delivery options that today’s online shoppers increasingly demand.

Manufacturing operations benefit from cross-docking’s support of just-in-time production. Components and materials arrive precisely when needed, reducing factory storage requirements and supporting lean manufacturing principles. For companies with cross-border supply chains between Canada and the US, this coordination helps overcome potential customs delays.

The automotive industry has long used cross-docking to manage complex supply chains. Parts from hundreds of suppliers converge at cross-docking facilities near assembly plants, arriving in sequence with production schedules. This precision helps manufacturers maintain efficient operations while minimizing costly production interruptions.

Today’s cross-docking success depends heavily on sophisticated technology systems that coordinate complex movements with precision. At the heart of these operations sits the warehouse management system (WMS), which orchestrates the entire process. Modern WMS platforms provide real-time inventory tracking, automatically directing where each item should go and when it should move.

Barcode scanning and RFID technology ensure accurate identification throughout the cross-docking process. Workers scan items upon arrival, during sorting, and at departure, creating a digital trail that prevents errors and losses. This visibility proves especially valuable for cross-border shipping between Canada and the US, where documentation accuracy is critical.

Transportation management systems complement WMS by optimizing inbound and outbound scheduling. These systems coordinate carrier arrivals and departures, ensuring docks remain productive throughout the day. They also support freight consolidation services by identifying opportunities to combine shipments heading to similar destinations.

Mobile technology puts critical information in workers’ hands wherever they are in the facility. Handheld devices display sorting instructions, verify proper loading, and capture digital signatures for proof of shipment. This mobility increases productivity while reducing paper documentation.

Data analytics tools help managers continuously improve cross-docking operations. By analyzing throughput rates, handling times, and error patterns, these systems identify bottlenecks and optimization opportunities. Canadian distribution centers use these insights to adapt processes for regional requirements, whether serving dense urban markets in Toronto or managing longer supply lines to northern communities.

As technology continues evolving, we’re seeing increased automation in cross-docking facilities, with some operations now incorporating robotics for routine sorting and movement tasks.

Despite its many benefits, cross-docking isn’t without challenges. Synchronization difficulties top the list of common problems. When inbound shipments arrive late or outbound transportation faces delays, the carefully orchestrated flow breaks down. This timing sensitivity makes cross-docking vulnerable to weather events, traffic congestion, and other disruptions common in Canadian logistics.

Space constraints present another frequent challenge. Effective cross-docking requires sufficient staging areas to sort and organize shipments between unloading and loading. In busy urban centers like Toronto or Vancouver, finding affordable facilities with adequate space can be difficult. Without proper design, cross-docking areas quickly become congested, leading to errors and inefficiency.

Information accuracy is critical yet challenging to maintain. Cross-docking depends on precise data about what’s arriving, when, and where it needs to go. Incorrect product information, missing documentation, or communication breakdowns between supply chain partners can cause significant disruptions. This challenge becomes even more pronounced in cross-border shipping between Canada and the US, where customs requirements add complexity.

Volume inconsistency affects many cross-docking operations. The model works best with steady, predictable flows. Seasonal spikes, promotional events, or irregular ordering patterns can overwhelm facilities during peak periods while leaving resources underutilized during slower times. This variability makes staffing and resource planning particularly difficult.

Product compatibility issues arise when handling diverse items through the same facility. Different products may require special handling, temperature control, or security measures that complicate the cross-docking process. Food, pharmaceuticals, and hazardous materials present particular challenges that require specialized procedures and sometimes separate handling areas.

At MacMillan Supply Chain Group, we’ve developed comprehensive solutions to address these common cross-docking challenges. Our approach begins with strategic facility design that optimizes flow and maximizes productivity. Our cross-docking centers feature flexible layouts with clearly defined zones for receiving, sorting, and shipping. We incorporate sufficient staging space to accommodate volume fluctuations while maintaining efficient operations.

To tackle synchronization challenges, we’ve implemented advanced scheduling systems that coordinate all transportation movements. Our proprietary software provides real-time visibility into inbound shipments, allowing us to adjust resources dynamically as conditions change. This adaptive approach ensures we maintain productivity even when facing unexpected delays or volume spikes.

Our technology infrastructure represents a significant advantage for clients. We’ve invested in state-of-the-art warehouse management systems that track every item through the cross-docking process with exceptional accuracy. These systems integrate seamlessly with our clients’ platforms, creating end-to-end visibility across the supply chain. For cross-border shipping between Canada and the US, our systems automatically generate and verify required documentation, minimizing delays and compliance issues.

Staff expertise makes a crucial difference in our cross-docking operations. We employ experienced logistics professionals who understand the nuances of efficient product handling. Our comprehensive training programs ensure all team members follow best practices for safety, accuracy, and productivity. This human element, combined with our technology systems, creates a resilient operation that can adapt to changing conditions.

For clients with specialized product requirements, we offer customized handling solutions. Our facilities include temperature-controlled areas for food and pharmaceutical products, secure zones for high-value items, and specialized equipment for handling unusual or fragile merchandise. This flexibility allows us to support diverse industry needs through a single cross-docking operation.

Volume variability receives particular attention in our approach. We maintain flexible staffing models that can scale up or down based on forecasted demand. Our relationships with reliable temporary staffing partners ensure we can quickly add qualified personnel during peak periods. Additionally, our network of facilities across Canada allows us to balance workloads between locations when necessary.

Communication excellence underpins everything we do. We maintain proactive contact with suppliers, carriers, and recipients to coordinate movements and address potential issues before they impact operations. Our client portal provides real-time status updates and performance metrics, creating transparency throughout the process.

For e-commerce fulfillment in Canada, our cross-docking solutions include value-added services like custom packaging, gift wrapping, and personalized inserts. These capabilities allow online retailers to enhance customer experience while maintaining efficient operations.

Our commitment to continuous improvement drives ongoing refinement of our cross-docking processes. We regularly analyze performance data to identify optimization opportunities and implement best practices across our network. This approach ensures our clients benefit from the most efficient, reliable cross-docking services available in the Canadian market.

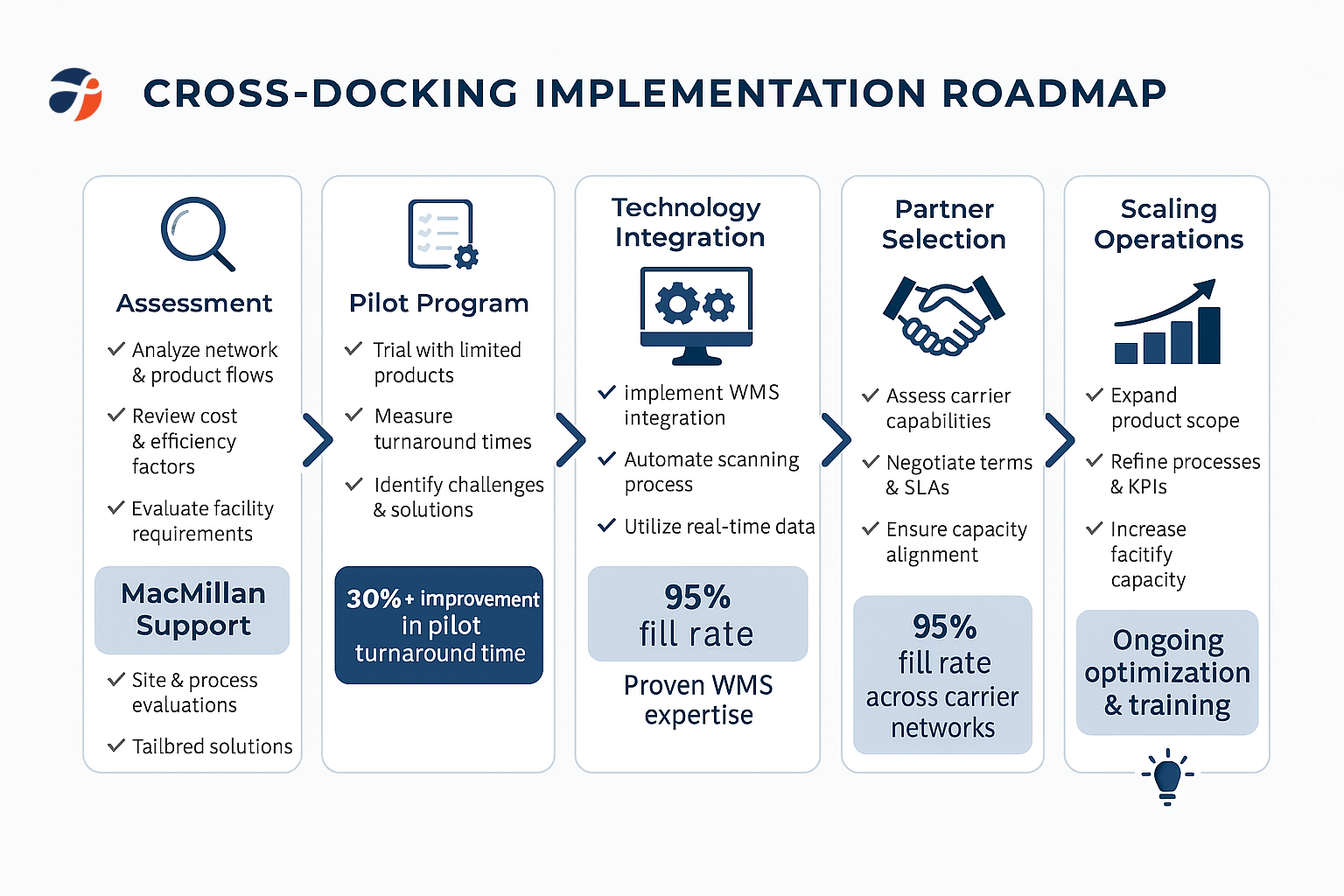

Ready to explore how cross-docking can transform your logistics operations? Start with a thorough assessment of your current supply chain. Identify products with consistent, predictable demand and relatively short shelf life—these typically benefit most from cross-docking. Also consider your geographic distribution patterns; cross-docking works best when serving multiple destinations from a central hub.

Begin with a pilot program rather than a complete overhaul. Select a subset of your product line or a specific geographic region to test cross-docking concepts. This approach allows you to refine processes and demonstrate value before scaling up. Many successful implementations start with 20-30% of volume and gradually expand as systems prove effective.

Technology readiness is essential for cross-docking success. Ensure your inventory management systems can provide real-time visibility and accurate forecasting. If your current technology falls short, consider upgrading before implementing cross-docking. The investment typically pays for itself through improved efficiency and reduced handling costs.

Partner selection deserves careful consideration. Look for logistics providers with proven cross-docking expertise and facilities in your key markets. The right partner brings not just physical infrastructure but also systems integration capabilities and operational knowledge that accelerate your implementation.

MacMillan Supply Chain Group offers comprehensive cross-docking solutions tailored to your specific needs. Our network of strategically located facilities across Canada supports efficient distribution to major markets and cross-border shipping to the US. Our team works closely with your organization to design optimal workflows, implement supporting technology, and train your staff on new processes.

When you partner with MacMillan, you gain access to our decades of logistics expertise and continuous innovation. We help you navigate the complexities of cross-docking implementation while avoiding common pitfalls. Our solutions scale with your business, providing flexibility to handle seasonal variations and growth without service disruptions.

Ready to explore how cross-docking can streamline your logistics operations? Contact MacMillan Supply Chain Group today for a consultation. Our experts will analyze your current processes and develop a customized cross-docking strategy that reduces costs, improves delivery times, and enhances customer satisfaction. Visit our website or call 1-888-999-9999 to start your cross-docking journey with a partner you can trust.

Cross-docking is a logistics strategy where products move directly from receiving to shipping with minimal storage time in between. Unlike traditional warehousing, where items might be stored for weeks or months, cross-docking keeps products moving, typically for less than 24 hours. This approach eliminates storage costs, reduces handling, and speeds up delivery times. At MacMillan Supply Chain Group, our cross-docking facilities are designed specifically for this rapid throughput model.

Products with consistent demand, time-sensitive delivery requirements, or short shelf lives gain the greatest advantages. These include fresh food, fashion merchandise, promotional items, and seasonal goods. Cross-docking also works well for consolidated shipments from multiple suppliers heading to the same destination. However, slow-moving items or products with unpredictable demand patterns may not be ideal candidates for this approach.

Cross-docking accelerates e-commerce operations by reducing handling steps and delivery times. When online orders arrive at our facilities, we can quickly sort and consolidate them for efficient last-mile delivery. This approach supports same-day or next-day shipping options that today's consumers expect. For Canadian e-commerce businesses competing with international giants, this speed advantage can be crucial for customer satisfaction and retention.

Successful cross-docking requires robust technology systems, starting with a warehouse management system (WMS) that provides real-time inventory visibility and location tracking. Barcode scanning or RFID technology ensures accurate identification throughout the process. Transportation management systems help coordinate inbound and outbound movements. At MacMillan, we've invested in these technologies and integrated them seamlessly to provide end-to-end visibility for our clients.

Cross-docking cuts transportation expenses through freight consolidation services that combine multiple smaller shipments into fuller truckloads. This consolidation reduces the total number of trips required, lowering fuel consumption and driver costs. For businesses shipping across Canada's vast geography or managing cross-border shipping between Canada and the US, these savings can be substantial—often 15-25% compared to direct shipping methods.

While traditionally associated with large retailers, cross-docking can benefit smaller businesses through shared facilities. By partnering with a 3PL provider like MacMillan Supply Chain Group, smaller companies can access cross-docking capabilities without investing in their own infrastructure. Our multi-client facilities allow businesses to share resources and costs while gaining efficiency benefits. We tailor our approach to your volume, ensuring scalable solutions as your business grows.

Cross-docking contributes to sustainability through several mechanisms. By consolidating shipments, it reduces the total number of trucks on the road, lowering carbon emissions. The minimal storage time means less energy consumed for warehouse lighting, heating, and cooling. Additionally, faster delivery reduces the need for excessive packaging that might otherwise be required to protect goods during extended storage. These environmental benefits align with growing consumer and regulatory expectations for sustainable business practices.

The biggest challenges include synchronization of inbound and outbound movements, information accuracy, and handling volume fluctuations. Cross-docking requires precise coordination between suppliers, carriers, and recipients. Without accurate product information and arrival times, the process breaks down quickly. MacMillan addresses these challenges through advanced scheduling systems, proactive communication protocols, and flexible staffing models that adapt to changing volume requirements.

Cross-border cross-docking requires additional expertise to navigate customs requirements efficiently. At MacMillan, our border-focused facilities include customs clearance capabilities that minimize delays. We prepare documentation in advance, work with trusted carriers familiar with border procedures, and maintain compliance with both Canadian and US regulations. This specialized approach ensures smooth movement of goods despite the additional complexity of international shipping.

Choose a partner with proven experience, strategic facility locations, and robust technology systems. Look for evidence of operational excellence and the ability to handle your specific product requirements. Ask about contingency planning for disruptions and capacity for handling volume fluctuations. Most importantly, ensure they understand your business needs and can customize their approach accordingly. MacMillan Supply Chain Group offers all these qualities, along with a commitment to continuous improvement that keeps your logistics operations at the cutting edge.