How Cross-Docking Streamlines Your Logistics Operations

A quick summary and overview Cross-docking transforms traditional logistics by…

A quick summary and overview Cross-docking transforms traditional logistics by…

Handling Hazards: How WHMIS-Compliant Logistics Protect Your Homecare Brand A…

AI’s Revolutionary Potential: 3PL Operating Systems Changing the game Logistics…

Introduction The world’s supply chains are more interconnected and vulnerable…

Canada’s supply chain landscape is evolving rapidly with companies leveraging advanced technology and innovative solutions to meet growing logistics demands. The top supply chain companies in Canada are distinguished by their ability to provide comprehensive 3PL services, warehouse automation, and seamless cross-border logistics. These market leaders are transforming traditional supply chain operations through e-commerce fulfillment excellence, sustainability initiatives, and strategic transportation networks. With the Canadian logistics market expected to grow significantly in coming years, understanding who’s leading the industry and their competitive advantages offers valuable insights for businesses seeking reliable supply chain partners in an increasingly complex marketplace.

The Canadian supply chain sector represents a dynamic ecosystem where traditional logistics meets cutting-edge innovation. With Canada’s vast geography spanning nearly 10 million square kilometers and a population concentrated along the southern border, supply chain companies face unique challenges in connecting businesses with customers efficiently. The industry has transformed dramatically in recent years, driven by e-commerce growth, changing consumer expectations, and technological advancements.

Top supply chain companies in Canada are distinguished by their ability to navigate these challenges while providing seamless logistics solutions. From warehouse automation to cross-border shipping expertise, these market leaders are reshaping how goods move throughout Canada and North America. Whether you’re a retailer looking for fulfillment services or a manufacturer needing transportation solutions, understanding who’s leading the Canadian supply chain market provides valuable insights into potential partnerships that can drive your business forward.

The Canadian third-party logistics (3PL) landscape features a mix of global giants and homegrown specialists who have established themselves as market leaders through comprehensive service offerings and technological innovation.

Metro Supply Chain Group stands as the largest Canadian-owned provider of third-party logistics services across the country. With operations expanding into the United States and United Kingdom, Metro has added nearly 1,000 team members in recent years, demonstrating significant growth. Their business philosophy of being “large enough to serve, small enough to care” resonates with clients seeking personalized service without sacrificing national coverage capabilities.

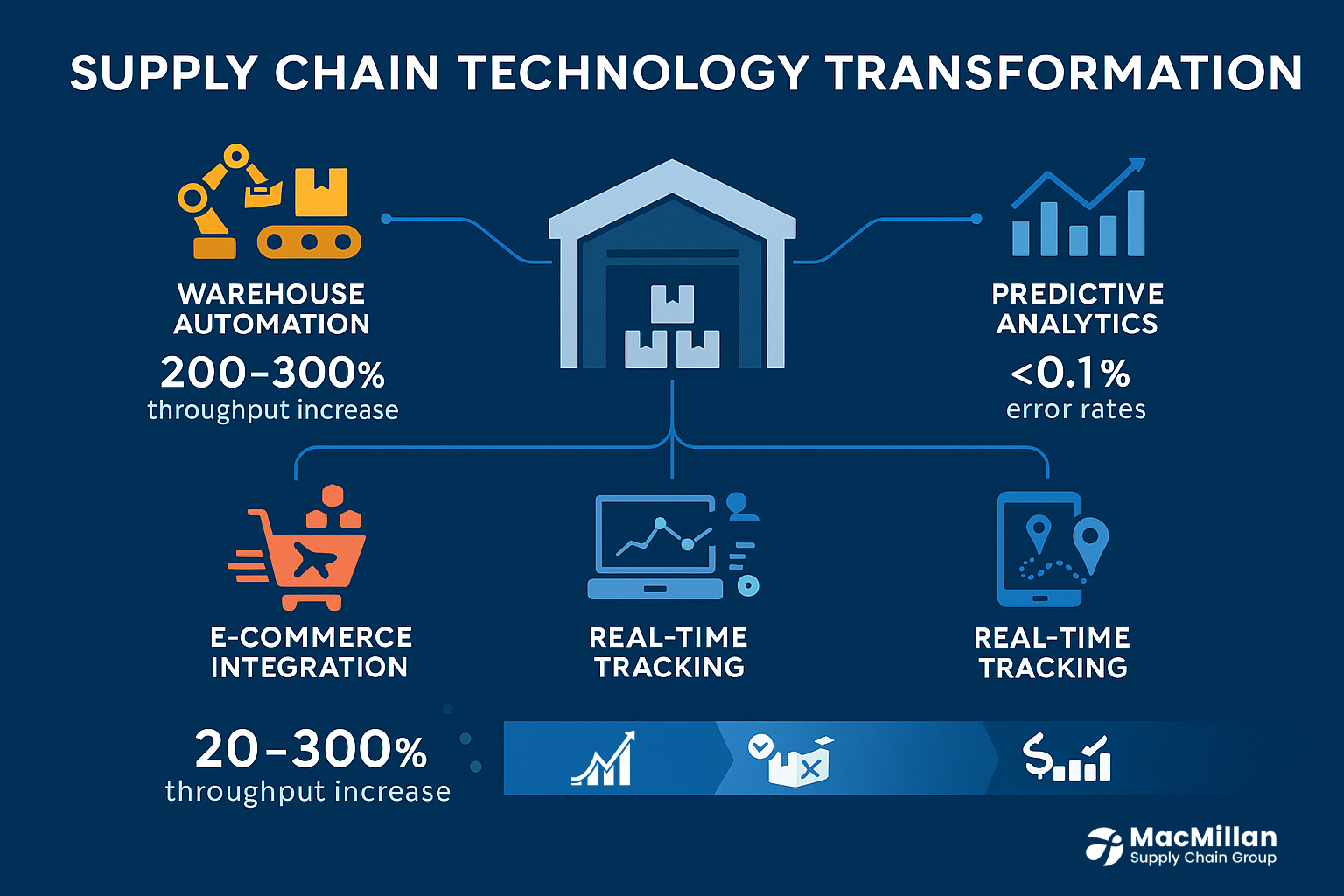

MacMillan Supply Chain Group, headquartered in Brampton, has emerged as a leader in e-commerce fulfillment and warehouse automation. Their technology-first approach integrates seamlessly with major platforms like Shopify and Amazon, making them an ideal partner for businesses scaling their online operations. MacMillan’s implementation of advanced warehouse automation has enabled clients to increase throughput by 200-300% during peak periods while maintaining error rates below 0.1%.

Canada Cartage/The GTI Group ranks among North America’s top logistics companies with approximately $824 million in annual revenue. Their expertise in temperature-controlled shipping and dedicated fleet services makes them particularly valuable for businesses with specialized transportation requirements. Their comprehensive approach to supply chain management addresses complex logistics challenges through customized solutions rather than one-size-fits-all offerings.

Other notable players include Integrity Express Logistics, known for excellence in cross-border logistics between Canada and the United States, and Saddle Creek Logistics Services, which has developed particular strength in temperature-controlled logistics and pharmaceutical distribution.

Technology has become the defining competitive advantage among top supply chain companies in Canada, with market leaders investing heavily in systems that enhance efficiency, visibility, and customer experience.

Warehouse automation represents one of the most significant areas of technological advancement in the Canadian logistics sector. Leading 3PL providers have implemented sophisticated systems including conveyor networks, pick-to-light technology, and collaborative robots that dramatically increase throughput capacity. MacMillan Supply Chain Group’s automation solutions enable 200-300% increases in processing volume during peak periods without proportional increases in labor costs – a critical advantage in today’s challenging employment market.

Predictive analytics has emerged as another crucial technology for managing seasonal demand fluctuations and optimizing inventory management. Advanced inventory systems provide real-time visibility across multiple warehouses, enabling proactive management of stock levels through dynamic reordering based on actual sales velocity rather than static thresholds. For seasonal items, specialized forecasting models account for historical performance, current market trends, and promotional calendars to prevent both stockouts and overstocks.

E-commerce integration capabilities have become essential for 3PL providers serving omnichannel retailers. Technology-first approaches integrate seamlessly with major platforms like Shopify, Amazon, and WooCommerce, demonstrating the importance of API connectivity and platform interoperability. This integration capability allows retailers to maintain consistent inventory visibility and order management across multiple sales channels while leveraging specialized fulfillment capabilities.

Real-time tracking and visibility systems have transformed customer expectations around shipment transparency. Leading logistics providers now offer sophisticated tracking solutions that provide minute-by-minute updates on shipment status, estimated delivery times, and potential delays. These systems not only enhance the customer experience but also enable proactive issue resolution before problems impact delivery performance.

Cross-border logistics between Canada and the United States represents one of the most critical capabilities for top supply chain companies in Canada. With approximately 75% of Canadian exports destined for the US market, expertise in navigating the complexities of cross-border trade has become a defining characteristic of market leaders.

Customs management capabilities distinguish the leading logistics providers in this space. Companies like Integrity Express Logistics have developed sophisticated systems for managing documentation requirements, duty calculations, and regulatory compliance across the Canada-US border. These systems streamline the customs clearance process, reducing delays and ensuring compliant movement of goods between the two countries.

Transportation networks optimized for cross-border trade represent another key advantage of market leaders. Companies operating dedicated fleets or managing carrier networks have developed specialized expertise in route optimization, border crossing selection, and timing strategies that minimize delays and maximize efficiency. This expertise becomes particularly valuable during periods of border congestion or when moving time-sensitive shipments.

Regulatory compliance expertise has become increasingly important as trade rules evolve and change. Leading logistics providers maintain dedicated teams focused on monitoring regulatory developments and ensuring client shipments meet all applicable requirements. This expertise extends beyond basic customs documentation to include product-specific regulations, security protocols, and specialized certification requirements.

Technology integration across borders enables seamless visibility and control throughout the entire shipment lifecycle. Top supply chain companies have invested in systems that maintain consistent tracking and management capabilities regardless of which side of the border a shipment is on. This integration eliminates information gaps and provides clients with comprehensive visibility from origin to destination.

Despite the sophistication of top supply chain companies in Canada, businesses still face significant challenges when managing cross-border logistics and domestic distribution. These challenges can impact efficiency, cost, and customer satisfaction if not properly addressed.

Customs delays represent one of the most persistent challenges in cross-border logistics. Even with proper documentation, shipments can face unexpected holds or inspections that disrupt delivery schedules and impact inventory planning. These delays become particularly problematic for time-sensitive shipments or businesses operating with lean inventory models that depend on predictable replenishment cycles.

Documentation errors frequently cause preventable delays and compliance issues. Missing information, incorrect classification codes, or inconsistent paperwork can result in customs holds, penalties, or even shipment rejections. For businesses without specialized expertise in international trade documentation, these errors can become a recurring source of frustration and cost.

Capacity constraints during peak seasons create challenges for businesses relying on standard shipping arrangements. During holiday periods or promotional events, transportation and warehouse capacity can become severely limited, resulting in higher costs and extended transit times. Without proper planning and partnerships, businesses may find themselves unable to secure the capacity needed to meet customer expectations during critical sales periods.

Inventory visibility gaps often emerge when products move between different systems or facilities. These gaps can result in inaccurate stock levels, misplaced inventory, or inability to locate specific items when needed for order fulfillment. For businesses operating across multiple channels or markets, maintaining consistent inventory visibility becomes increasingly complex without sophisticated systems integration.

Last-mile delivery challenges persist despite significant industry innovation. Delivering to residential addresses, particularly in rural areas or during inclement weather, remains one of the most expensive and unpredictable aspects of the supply chain. These challenges directly impact customer satisfaction and can undermine otherwise excellent logistics performance if not properly managed.

MacMillan Supply Chain Group has developed comprehensive solutions to address the common challenges facing businesses operating in the Canadian and North American markets. Our approach combines specialized expertise, advanced technology, and strategic infrastructure to create seamless supply chain experiences for our clients.

Our customs management solutions eliminate the uncertainty and delays associated with cross-border shipping. Our dedicated customs compliance team maintains current expertise in regulatory requirements and documentation standards, ensuring shipments move smoothly across the Canada-US border. We provide:

Our warehouse automation systems address capacity constraints and seasonal fluctuations through scalable processing capabilities. Our facilities feature:

Our inventory management platform eliminates visibility gaps through comprehensive tracking and integration capabilities. The system provides:

Our transportation optimization solutions address delivery challenges through strategic carrier selection and route planning. We leverage:

Our e-commerce integration capabilities eliminate the complexity of managing multiple sales channels. Our platform:

By combining these solutions into a comprehensive logistics strategy, MacMillan Supply Chain Group enables clients to overcome the common challenges of Canadian and cross-border supply chains. Our approach transforms potential problems into competitive advantages through specialized expertise, advanced technology, and strategic infrastructure.

Implementing an effective supply chain strategy doesn’t have to be complicated. By partnering with MacMillan Supply Chain Group, businesses can transform their logistics operations and gain competitive advantages without massive internal investments or disruptions.

Start with a comprehensive assessment of your current operations. Our supply chain consulting team will analyze your existing processes, identify opportunities for improvement, and develop a customized implementation plan. This assessment typically examines:

Implement in phases rather than attempting a complete transformation at once. Our staged implementation approach minimizes disruption while delivering incremental improvements throughout the process. A typical implementation might include:

Leverage our technology platform without significant capital investment. Our systems provide sophisticated capabilities without requiring clients to purchase, implement, and maintain complex software. Key technology advantages include:

Benefit from our specialized expertise in Canadian logistics and cross-border trade. Our team brings decades of experience navigating the unique challenges of the Canadian market, providing insights and solutions that generic logistics providers simply can’t match.

Ready to transform your supply chain with a partner who understands the Canadian market? Contact MacMillan Supply Chain Group today to schedule your initial consultation. Our team will work with you to develop a customized solution that addresses your specific challenges and objectives, creating a logistics strategy that drives growth and customer satisfaction.

Visit our website or call 1-800-XXX-XXXX to speak with a supply chain specialist and begin your transformation journey.

MacMillan Supply Chain Group distinguishes itself through a combination of advanced technology, specialized Canadian market expertise, and a customer-centric approach. Unlike many larger providers that offer standardized solutions, we develop customized strategies that address each client's specific challenges and objectives. Our warehouse automation systems increase throughput by 200-300% during peak periods while maintaining error rates below 0.1%, significantly outperforming industry averages. Additionally, our deep expertise in cross-border logistics between Canada and the United States enables seamless movement of goods throughout North America, eliminating the complexity and delays that often impact international shipments.

Leading Canadian supply chain companies approach e-commerce fulfillment as a specialized discipline rather than simply an extension of traditional warehouse operations. This includes implementing dedicated technology systems that integrate directly with major e-commerce platforms, developing specialized packaging protocols that balance protection with dimensional weight considerations, and creating flexible staffing models that accommodate the variable order volumes characteristic of online retail. The best providers also offer value-added services such as custom packaging, gift wrapping, and personalized inserts that enhance the unboxing experience for end customers. These specialized capabilities enable retailers to deliver consistent brand experiences through the fulfillment process rather than treating it as simply a transactional function.

Warehouse automation delivers multiple benefits including increased processing speed (typically 2-3x faster than manual operations), improved accuracy (99.9%+ compared to 96-98% for manual picking), reduced labor costs (30-50% savings in many operations), better space utilization (15-25% improvement through more efficient storage systems), and enhanced scalability to handle volume fluctuations without proportional staffing increases. These improvements translate to faster order fulfillment, fewer errors, lower operational costs, and the ability to reliably meet customer expectations even during peak periods.

Warehouse automation systems dramatically improve both speed and accuracy in fulfillment operations through technologies that eliminate manual processes and human error. Advanced conveyor systems move products efficiently through the facility while reducing handling damage. Pick-to-light technology guides operators to the correct inventory locations and quantities, reducing selection errors by up to 99%. Automated sortation systems ensure orders are directed to the appropriate packing stations and shipping methods. Collaborative robots handle repetitive tasks while allowing human workers to focus on complex operations requiring judgment and dexterity. Together, these technologies enable fulfillment operations that are not only faster but also significantly more accurate than traditional manual processes.

Successful cross-border logistics between Canada and the United States depends on several critical factors. Comprehensive documentation preparation ensures all required information is accurate and complete before shipments reach the border. Strategic carrier selection identifies transportation providers with established cross-border expertise and dedicated lanes. Customs compliance expertise prevents delays through proper classification, valuation, and origin determination. Technology integration maintains visibility throughout the entire shipment lifecycle regardless of which side of the border the goods are on. Contingency planning addresses potential disruptions such as weather events, system outages, or inspection delays. By managing these factors effectively, top supply chain companies in Canada create seamless cross-border experiences that eliminate the complexity traditionally associated with international shipping.

Leading Canadian supply chain companies are implementing comprehensive sustainability initiatives that address environmental impact throughout the logistics process. These include transitioning to electric vehicles for last-mile delivery, implementing energy-efficient lighting and climate control systems in warehouse facilities, optimizing transportation routes to reduce fuel consumption and emissions, developing packaging solutions that minimize waste while maintaining product protection, and implementing recycling programs for packaging materials and operational waste. The most advanced providers also offer carbon offset programs that enable clients to neutralize the environmental impact of their logistics operations. These initiatives not only reduce environmental impact but often deliver operational cost savings through improved efficiency and reduced resource consumption.

When evaluating warehouse space in the Greater Toronto Area, businesses should consider several critical factors beyond basic square footage and lease rates. Location relative to major transportation corridors significantly impacts inbound and outbound shipping costs and transit times. Ceiling height affects storage capacity and racking options, with modern facilities typically offering 32-40 foot clear heights. Dock door quantity and configuration influence loading/unloading capacity and efficiency. Floor load capacity determines suitable storage methods and equipment. Power capacity affects the ability to operate automation systems and maintain appropriate climate control. Additionally, businesses should evaluate expansion options, shared services arrangements, and facility certifications for specialized products such as food or pharmaceuticals. Working with experienced 3PL providers can help navigate these considerations and identify optimal solutions.

Seasonal demand fluctuations create significant challenges for Canadian supply chain operations, particularly during holiday periods and promotional events when order volumes can increase by 300-400% compared to baseline levels. These fluctuations impact staffing requirements, warehouse space utilization, transportation capacity, and system processing capabilities. Top supply chain companies address these challenges through flexible staffing models that combine core employees with temporary workers during peak periods, modular warehouse configurations that adapt to changing inventory profiles, transportation contracts that guarantee capacity during high-demand periods, and scalable technology systems that maintain performance under increased transaction volumes. Additionally, advanced planning and forecasting capabilities help anticipate and prepare for seasonal peaks before they occur.

Supply chain consulting plays a crucial role in identifying opportunities for operational improvement and developing strategic roadmaps for implementation. Expert consultants bring industry benchmarks and best practices that help businesses understand their current performance relative to market leaders. They conduct comprehensive assessments that examine process flows, technology utilization, facility layout, staffing models, and carrier relationships to identify inefficiencies and bottlenecks. Based on these assessments, consultants develop customized improvement strategies that address specific challenges and objectives. They also provide implementation support that ensures theoretical improvements translate into practical results. For businesses without internal logistics expertise, supply chain consulting provides access to specialized knowledge without the cost of maintaining that expertise internally.

Measuring the ROI of a supply chain partnership involves quantifying both direct cost savings and operational improvements. Direct cost metrics include reduced transportation spend through carrier optimization, lower labor costs through improved productivity, decreased inventory carrying costs through better management, and reduced damage and loss claims through improved handling. Operational improvements include faster order processing times that enable later cutoff times for next-day delivery, improved order accuracy that reduces returns and customer service issues, enhanced inventory visibility that prevents stockouts and overstocks, and increased scalability that accommodates growth without proportional cost increases. The most comprehensive ROI calculations also consider customer experience improvements that drive retention and lifetime value, such as consistent on-time delivery and accurate order fulfillment.