Cobots & Labor-Tech Solving Canada Warehouse Worker Shortage

The critical 11% vacancy rate in transportation and warehousing that…

The critical 11% vacancy rate in transportation and warehousing that…

Growing tariffs, geopolitical unrest, and changing manufacturing environments present the…

Trump’s 50% Steel Tariffs: Industry Pushback and Supply Chain Disruption…

Businesses approaches to supply chain management were drastically altered by…

E-commerce fulfillment encompasses everything from inventory storage to order processing, picking, packing, shipping, and returns management. For Canadian online retailers, mastering these operations is crucial for business success. This guide breaks down the essential steps of e-commerce fulfillment, explores cutting-edge technologies transforming the industry, and provides actionable strategies to optimize your fulfillment process. Whether you’re handling fulfillment in-house or partnering with a 3PL provider, understanding these fundamentals will help you deliver exceptional customer experiences while managing costs effectively.

In today’s fast-paced digital marketplace, e-commerce fulfillment has become the backbone of online retail success. When a customer clicks “buy now,” they set in motion a complex chain of events that determines whether their experience will be delightful or disappointing. With Canadian e-commerce sales projected to reach $92.7 billion in 2025, businesses that master fulfillment gain a significant competitive advantage.

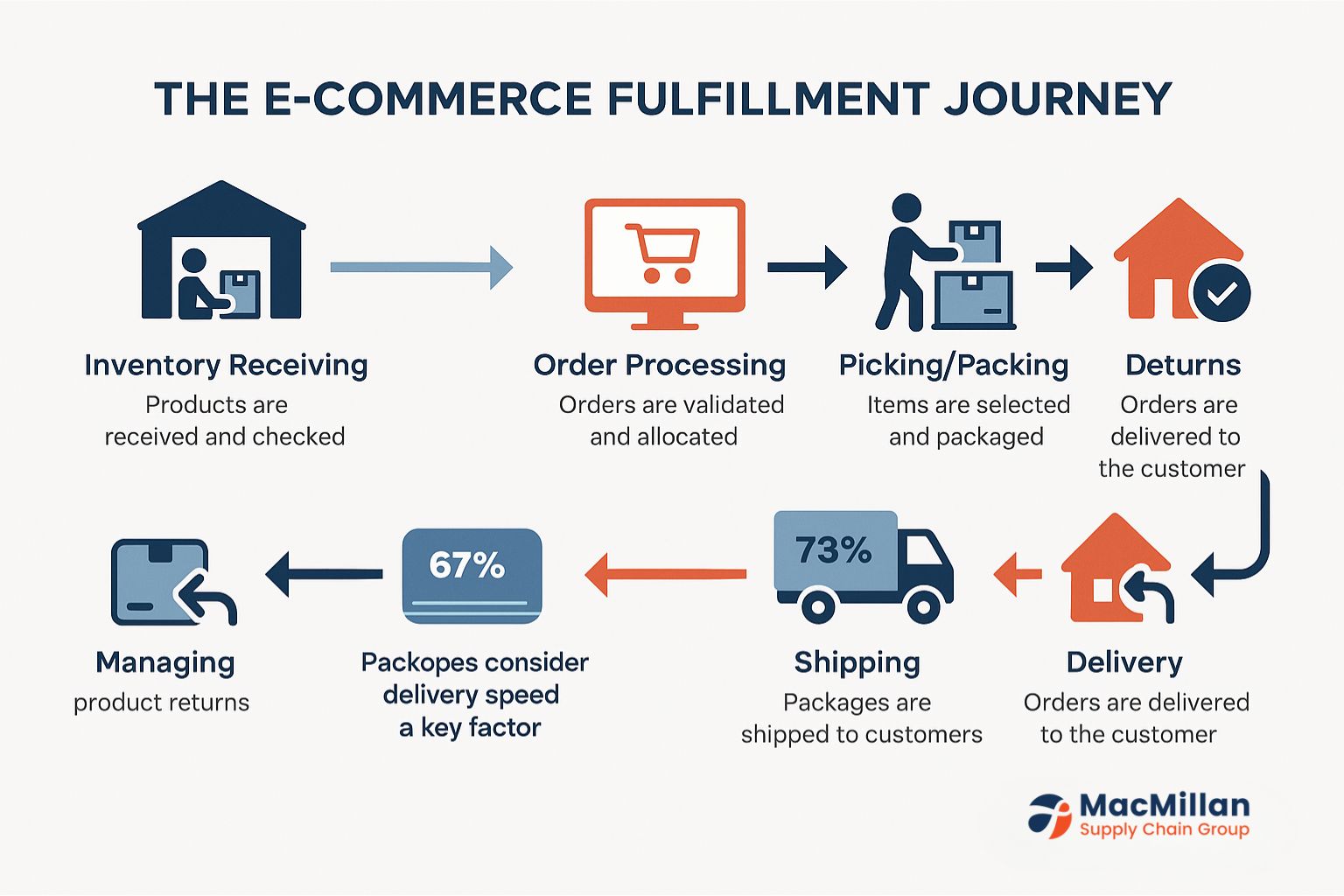

E-commerce fulfillment isn’t just about shipping packages—it’s about creating customer experiences that build loyalty and drive repeat business. Research shows that 73% of shoppers consider delivery speed a key factor in their purchasing decisions, while 69% are less likely to shop with a retailer again after a poor delivery experience. For Canadian businesses competing with global giants, optimizing the fulfillment process isn’t optional—it’s essential for survival and growth.

This guide will walk you through each step of the e-commerce fulfillment journey, from receiving inventory to managing returns, with practical insights to help your business thrive in this competitive landscape.

E-commerce fulfillment encompasses the complete journey of getting products from your warehouse to your customer’s doorstep. This process begins the moment a customer places an order and continues until they receive their package—and sometimes beyond, if returns are involved.

For Canadian businesses, understanding each step in this process is crucial for building efficient operations. The fulfillment journey typically includes receiving inventory, warehousing, order processing, picking and packing, shipping, delivery, and returns management. Each stage requires careful planning and execution to ensure customer satisfaction.

The importance of fulfillment can’t be overstated—it directly impacts your bottom line. Research shows that 38% of customers will abandon their cart if delivery takes longer than a week, while 45% are unlikely to shop with a retailer again after a late delivery. By optimizing your fulfillment process, you’re not just shipping products—you’re building customer relationships and strengthening your brand.

Modern fulfillment has evolved beyond simple shipping. Today’s consumers expect fast delivery, accurate order fulfillment, and transparent tracking information. Meeting these expectations requires a combination of strategic planning, technology integration, and sometimes partnerships with specialized providers like 3PLs. For Canadian retailers looking to compete with larger players, mastering these elements is the key to standing out in a crowded marketplace.

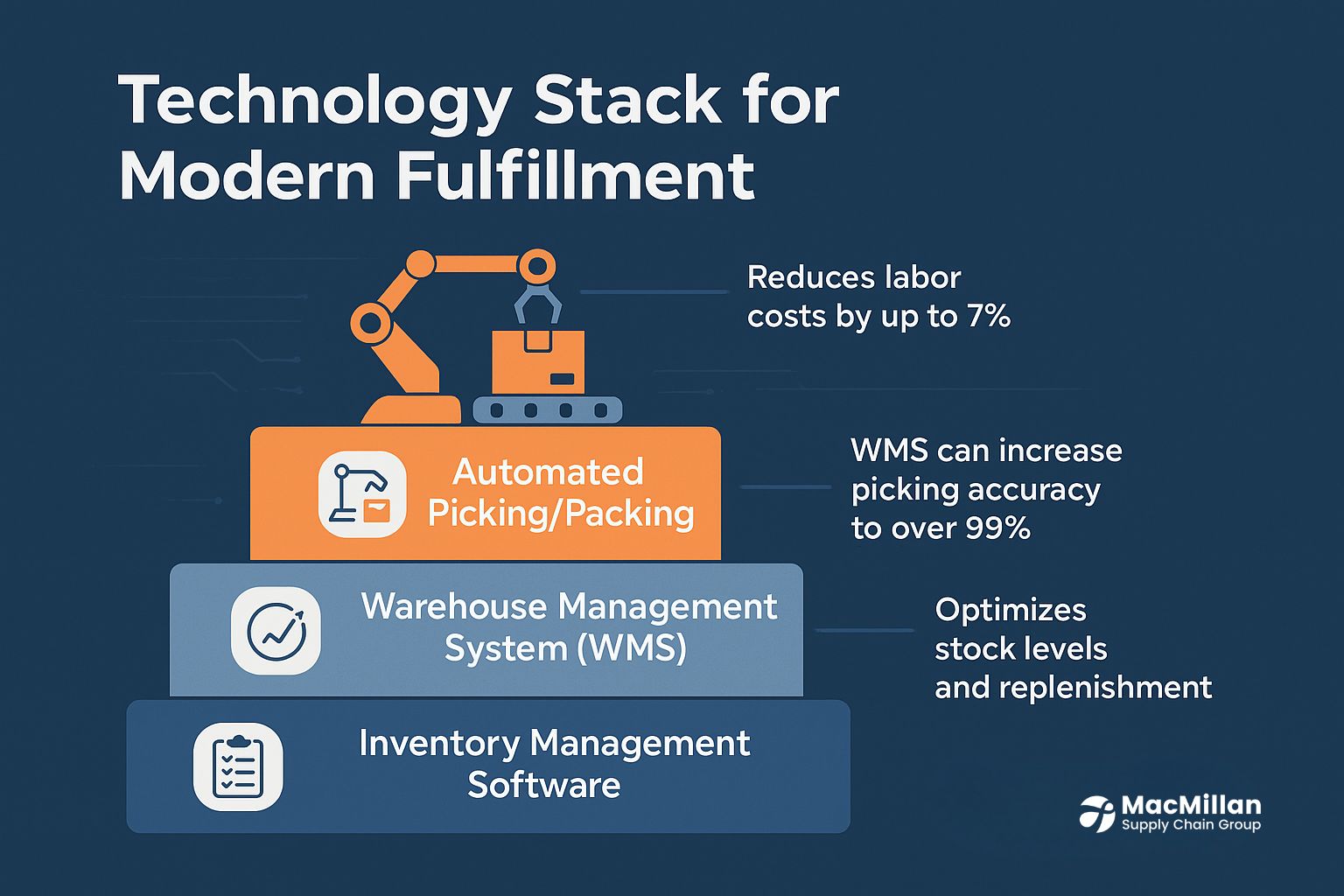

The technology powering e-commerce fulfillment has transformed dramatically in recent years, creating opportunities for businesses of all sizes to operate more efficiently. Implementing the right tech stack can be the difference between struggling with manual processes and running a streamlined operation that delights customers.

Inventory management software forms the foundation of effective fulfillment. These systems provide real-time visibility into stock levels, automatically trigger reorders when inventory runs low, and help prevent the costly mistake of overselling products. For Canadian businesses managing inventory across multiple locations or channels, these tools are invaluable for maintaining accuracy and preventing stockouts that frustrate customers.

Warehouse management systems (WMS) take efficiency to the next level by optimizing how products are stored, picked, and packed. A good WMS can increase picking accuracy to over 99% while reducing labor costs by 15-20%. These systems map warehouse layouts, direct staff along optimal picking routes, and ensure inventory is stored in locations that minimize travel time during order fulfillment.

Automated picking and packing technologies are revolutionizing fulfillment centers across Canada. From simple barcode scanners that reduce human error to sophisticated robotic systems that can pick hundreds of items per hour, automation helps businesses scale operations without proportionally increasing labor costs. Even small operations can benefit from semi-automated solutions that boost productivity while maintaining flexibility.

The integration of these technologies creates a seamless flow of information from the moment a customer places an order to when it arrives at their door. This connectivity eliminates data silos, reduces manual entry errors, and provides valuable insights that help businesses continuously improve their fulfillment operations.

Shipping represents one of the largest expenses in e-commerce fulfillment, but it also offers significant opportunities for optimization. Strategic approaches to shipping can reduce costs while improving customer satisfaction—a winning combination for any online retailer.

Shipping cost optimization starts with understanding dimensional weight pricing, which most carriers use to calculate shipping rates. By using appropriately sized packaging and minimizing void fill, businesses can avoid paying to ship “air” and reduce costs by 10-15%. Canadian retailers should also consider negotiating rates with multiple carriers rather than relying on a single shipping partner, as this competition can lead to better pricing and service.

Last-mile delivery optimization focuses on the final and most expensive leg of the shipping journey. Strategies include using regional carriers for certain areas, implementing zone skipping for high-volume destinations, and exploring alternative delivery options like pickup points. For urban Canadian markets, same-day delivery is becoming increasingly important, with 30% of shoppers willing to pay a premium for this service.

Cross-border shipping to the US presents both challenges and opportunities for Canadian e-commerce businesses. While navigating customs requirements adds complexity, accessing the massive US market can significantly boost sales. Successful cross-border strategies include clear communication about duties and taxes, partnering with experienced carriers, and considering fulfillment centers on both sides of the border for faster delivery.

B2C shipping in Canada has unique challenges, including vast geographic distances and relatively low population density outside major urban centers. Successful retailers address these challenges by strategically locating inventory, offering realistic delivery timeframes based on region, and providing transparent tracking information to set appropriate customer expectations.

Many growing e-commerce businesses reach a point where managing fulfillment in-house becomes overwhelming. This is where 3PL providers in Canada offer valuable solutions that can transform operations and support business growth.

3PL providers (third-party logistics) specialize in handling warehousing, fulfillment, and shipping for other companies. They bring expertise, infrastructure, and economies of scale that would be difficult for most businesses to develop independently. For Canadian retailers, partnering with a 3PL can provide immediate access to sophisticated fulfillment capabilities without the capital investment of building these systems from scratch.

The benefits of working with a 3PL extend beyond cost savings. These partners offer scalability during seasonal peaks, geographic reach through multiple fulfillment centers, and technology integration that connects with your existing e-commerce platforms. Many 3PLs also provide value-added services like kitting, custom packaging, and specialized handling for fragile or regulated products.

Choosing the right 3PL partner requires careful evaluation. Key considerations include geographic coverage, technology capabilities, pricing structure, and cultural fit. The best partnerships function as extensions of your business, with the 3PL understanding your brand values and customer expectations. For Canadian businesses looking to expand nationally or internationally, finding a 3PL with experience in cross-border shipping to the US and global markets can be particularly valuable.

When implemented successfully, 3PL partnerships allow e-commerce businesses to focus on their core competencies—product development, marketing, and customer relationships—while leaving the complexities of fulfillment to specialists. This strategic approach often leads to improved customer satisfaction, reduced operational headaches, and accelerated growth.

Even well-established e-commerce operations encounter fulfillment challenges that can impact customer satisfaction and profitability. Recognizing these common problems is the first step toward developing effective solutions.

Inventory management issues top the list of fulfillment challenges. Stockouts frustrate customers and lead to lost sales, while overstocking ties up capital and warehouse space. Many businesses struggle to forecast demand accurately, especially for new products or during seasonal fluctuations. Without robust inventory management software, maintaining the delicate balance between having enough stock to meet demand without excessive surplus becomes nearly impossible.

Order accuracy problems create costly returns and dissatisfied customers. Research shows that 23% of returns are due to incorrect items being shipped. These errors often stem from manual picking processes without verification systems, inadequate training, or confusing warehouse organization. Each mistake not only generates return shipping costs but also damages customer trust and potentially leads to negative reviews.

Shipping delays represent another major challenge, particularly for Canadian retailers dealing with vast geographic distances. Weather disruptions, carrier capacity limitations during peak seasons, and customs delays for cross-border shipments can all impact delivery timelines. Without contingency planning and clear communication with customers, these delays can significantly damage the shopping experience.

Returns management presents unique difficulties, with e-commerce return rates averaging 20-30%—much higher than brick-and-mortar retail. Many businesses lack efficient processes for receiving, inspecting, and reintegrating returned items into inventory. This creates bottlenecks, increases processing costs, and often results in merchandise that could be resold sitting idle or being unnecessarily discarded.

Peak season fulfillment challenges intensify these problems, as order volumes can increase by 35-40% during holiday periods. Without adequate planning for additional labor, extended carrier cutoff times, and potential supply chain disruptions, businesses risk disappointing customers during the most critical sales periods of the year.

At MacMillan Supply Chain Group, we’ve developed comprehensive solutions to address the common fulfillment challenges facing Canadian e-commerce businesses. Our integrated approach combines advanced technology, strategic processes, and experienced personnel to transform fulfillment from a business challenge into a competitive advantage.

For inventory management issues, we implement multi-layered solutions starting with advanced inventory management software that provides real-time visibility across all storage locations. Our predictive analytics capabilities help forecast demand based on historical data, seasonal patterns, and market trends, reducing both stockouts and overstock situations. We maintain safety stock levels customized to each product’s demand patterns and lead times, ensuring availability while minimizing carrying costs.

To solve order accuracy problems, our fulfillment warehouse in Canada utilizes barcode scanning technology and automated verification systems at multiple checkpoints throughout the picking and packing process. This multi-stage verification approach has helped our clients achieve accuracy rates exceeding 99.8%. Our warehouse layout is optimized with similar-looking products stored separately to prevent confusion, and our comprehensive training program ensures all team members understand the importance of precision in every order.

Addressing shipping delays requires both preventive strategies and responsive solutions. We maintain relationships with multiple carrier partners, allowing us to route packages through the most reliable service for each destination. During peak periods, we secure additional capacity commitments in advance to prevent bottlenecks. Our proprietary delivery estimation algorithm considers not just distance but historical carrier performance data for each route, providing customers with realistic delivery timeframes they can trust.

Our e-commerce returns management system transforms a traditional pain point into an opportunity for customer satisfaction. We’ve streamlined the returns process with automated return authorization, clear tracking, and rapid processing upon receipt. Our detailed inspection protocols and sophisticated inventory systems allow returned products to be quickly assessed and routed for restocking, refurbishment, or liquidation as appropriate, maximizing recovery value.

For peak season challenges, we implement comprehensive planning that begins months in advance. This includes temporary workforce expansion with thorough training, extended operating hours, pre-stocking of popular items, and reserved carrier capacity. Our scalable warehouse management system handles volume spikes without performance degradation, ensuring consistent service quality even during the busiest periods.

Cross-border shipping to the US becomes seamless through our specialized expertise in customs documentation, duties calculation, and compliance requirements. We maintain fulfillment centers strategically located for efficient cross-border commerce, reducing delivery times and minimizing customs delays. Our team stays current on regulatory changes, ensuring shipments move smoothly across the border without unexpected complications.

Last-mile delivery optimization is achieved through our sophisticated routing technology that selects the optimal carrier and service level for each shipment based on destination, package characteristics, delivery timeframe, and cost. For urban markets, we offer same-day delivery options through our network of courier partners, while our regional carrier relationships provide cost-effective solutions for more remote areas.

Sustainable packaging solutions are integrated throughout our operations, with right-sized packaging that minimizes waste while ensuring product protection. We use eco-friendly materials wherever possible and continuously evaluate new options as they become available. This approach not only reduces environmental impact but also lowers shipping costs through dimensional weight optimization.

Our technology integration capabilities ensure seamless connection between your e-commerce platform and our fulfillment systems, eliminating manual order entry and providing real-time visibility into order status, inventory levels, and fulfillment performance metrics. This connectivity enables data-driven decision making and continuous improvement across all aspects of the fulfillment process.

Implementing effective fulfillment solutions requires a strategic approach that balances immediate needs with long-term growth objectives. Whether you’re handling fulfillment in-house or partnering with a 3PL, these implementation steps will help you build a robust fulfillment operation.

Start by assessing your current fulfillment process to identify strengths and weaknesses. Analyze key metrics like order accuracy, processing time, shipping costs, and return rates to establish a baseline. This data-driven approach helps prioritize improvements that will deliver the greatest impact on customer satisfaction and operational efficiency.

For technology implementation, take an incremental approach rather than attempting a complete overhaul all at once. Begin with foundational systems like inventory management software that integrates with your e-commerce platform. Once these core systems are functioning smoothly, add more sophisticated tools like automated picking systems or predictive analytics capabilities. This phased approach minimizes disruption while allowing your team to adapt to new processes.

When selecting fulfillment partners, look beyond cost to evaluate factors like technology compatibility, geographic coverage, service level guarantees, and cultural alignment with your business values. The right partner should feel like an extension of your team, understanding your products and customer expectations. For Canadian businesses, finding a partner with expertise in both domestic and cross-border fulfillment provides flexibility for future growth.

Staff training is critical for fulfillment success, regardless of whether you’re operating in-house or with a 3PL. Ensure everyone understands not just the mechanics of fulfillment processes but also the importance of their role in customer satisfaction. Regular refresher training helps maintain high standards and introduces team members to process improvements and new technologies.

Continuous improvement should be built into your fulfillment strategy through regular performance reviews and feedback loops. Establish key performance indicators (KPIs) that align with your business goals, and review these metrics at least monthly to identify trends and opportunities for optimization. Customer feedback provides valuable insights that may not be captured in operational metrics, so incorporate this perspective into your improvement process.

Ready to transform your e-commerce fulfillment? MacMillan Supply Chain Group offers comprehensive fulfillment solutions tailored to Canadian businesses of all sizes. Our team of experts can help you navigate the complexities of modern fulfillment, from technology integration to cross-border shipping strategies.

Contact MacMillan Supply Chain Group today for a personalized consultation. Our specialists will analyze your current operations and recommend customized solutions to improve efficiency, reduce costs, and enhance customer satisfaction. With our strategic locations across Canada, advanced technology platform, and decades of logistics expertise, we’re uniquely positioned to help your business thrive in the competitive e-commerce landscape.

Don’t let fulfillment challenges limit your growth potential. Partner with MacMillan Supply Chain Group and turn your fulfillment operation into a competitive advantage that drives customer loyalty and business success.

E-commerce fulfillment encompasses the entire process of receiving, storing, processing, and shipping online orders to customers. It includes inventory management, order processing, picking and packing products, shipping, delivery tracking, and returns handling. Effective fulfillment ensures customers receive the right products, in good condition, within the expected timeframe—creating a positive experience that encourages repeat purchases.

Consider outsourcing to a 3PL when: your order volume exceeds 500 monthly orders; fulfillment is taking time away from core business activities; you need seasonal scalability; shipping costs are rising; order accuracy is declining; or you’re expanding into new markets. 3PLs offer economies of scale, specialized expertise, and technology that most businesses couldn’t justify developing independently. The right time varies by business, but these indicators suggest you’d benefit from exploring 3PL partnerships.

The foundation of efficient fulfillment is robust inventory management software that provides real-time visibility and prevents stockouts or overselling. A warehouse management system (WMS) optimizes storage and picking processes. Order management systems ensure seamless processing across sales channels. Barcode scanning or RFID technology improves accuracy, while shipping software compares carrier rates. For larger operations, automated picking and packing systems can significantly increase throughput and reduce labor costs.

Optimize packaging by using appropriate box sizes to minimize dimensional weight charges. Negotiate rates with multiple carriers rather than relying on a single provider. Consider zone skipping for high-volume destinations. Strategically position inventory closer to customer concentrations to reduce shipping distances. Offer incentives for customers to bundle multiple items in a single order. For Canadian businesses, explore regional carriers for domestic shipments and specialized cross-border services for US deliveries.

The main challenges include customs documentation, duties and taxes calculation, longer transit times, and higher return costs. Address these by using automation tools that generate accurate customs forms, clearly communicating potential duties to customers at checkout, partnering with carriers specializing in cross-border shipping, and considering US-based fulfillment centers for high-volume markets. Understanding harmonized system (HS) codes and staying current on trade regulations is also essential for smooth cross-border operations.

Create a clear, simple returns policy and make it easily accessible on your website. Provide pre-printed return labels and simple instructions with each order. Process returns quickly upon receipt, with prompt refunds or exchanges. Implement a systematic inspection process to determine whether items can be restocked, need refurbishment, or should be liquidated. Analyze return reasons to identify and address product issues. Consider restocking fees for non-defective returns while maintaining flexibility for loyal customers.

Implement a centralized inventory management system that synchronizes stock levels across all channels in real-time to prevent overselling. Consider safety stock levels for each channel based on historical sales patterns. Use forecasting tools that account for channel-specific trends and seasonality. For marketplace sales, develop buffer strategies that account for their specific fulfillment requirements. Regular reconciliation between physical inventory and system records helps maintain accuracy across all channels.

Start planning at least 3-4 months in advance. Analyze historical data to forecast inventory needs and pre-stock popular items. Secure additional warehouse space if needed. Develop a staffing plan that includes temporary workers and training schedules. Communicate early with shipping carriers about volume projections and secure capacity commitments. Implement cutoff dates for guaranteed holiday delivery and communicate these clearly to customers. Test systems under load conditions before the peak period begins.

Key metrics include order accuracy rate (target: >99%), order processing time (from receipt to shipping), on-time delivery percentage, shipping cost per order, inventory turnover rate, perfect order percentage (orders delivered complete, on time, and damage-free), return rate by reason, and average time to process returns. Customer satisfaction metrics like Net Promoter Score (NPS) or post-purchase surveys provide valuable context for operational metrics.

Sustainable packaging is increasingly important to consumers, with 67% considering eco-friendliness when making purchasing decisions. Businesses should evaluate right-sized packaging to eliminate excess materials, explore recyclable or biodegradable alternatives to traditional plastics, and communicate sustainability efforts to customers. While some eco-friendly materials may cost more initially, they often reduce dimensional weight charges and resonate with environmentally conscious consumers. Start with simple changes like minimizing void fill and eliminating plastic where possible.